FEATURES

Suitable medium:Water, steam, oil, etc

Application:Water treatment, petrochemical industry, food and medicine, power and energy, metallurgy, etc

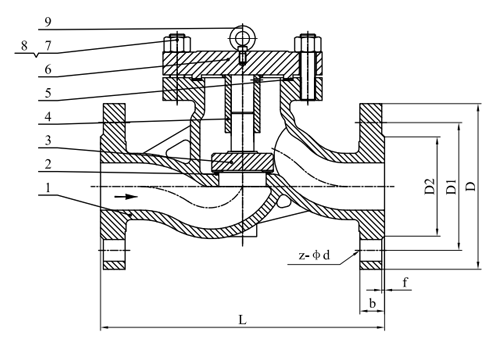

Product Identification:

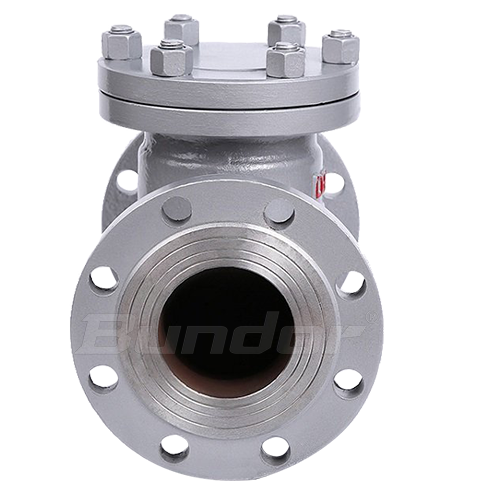

Lift check valve is a check valve where the valve disc slides along the vertical centerline of the valve body. When the medium flows downstream, the valve disc opens against the medium thrust. When the medium stops flowing, the valve disc lands vertically on the valve seat to prevent reverse flow of the medium. Lift check valve should be installed on a horizontal pipeline; Widely applicable to pipelines under various working conditions such as water treatment, petroleum, chemical, thermal power plants, etc.Nominal pressure can be PN16-PN100, working temperature can meet -29~425 ℃. Its main function is to prevent medium backflow and prevent the pump and its driving motor from reversing.

Product Advantages:

1. Precision casting valve body. Qualified WCB material. Fine appearance, no sand hole.

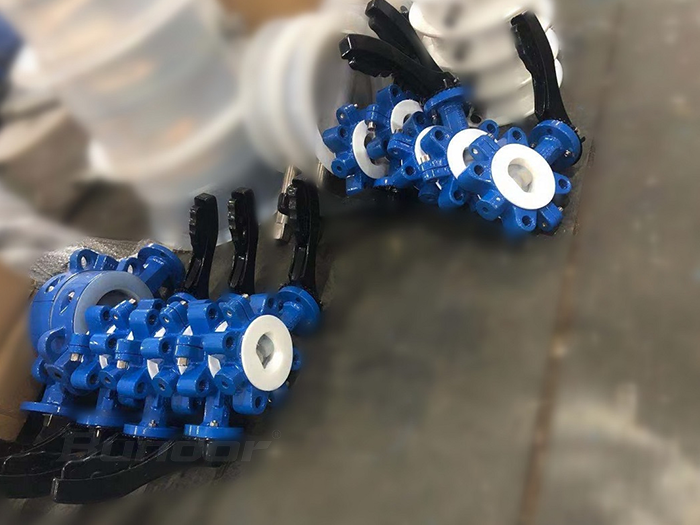

2. CNC machining components,two times of shot blasting treatments,smooth and nice appearance

3. Overlay welding of Cr13 on the valve seat to increase the wear resistance of the valve seat.

4. Each valve will be inspected for shell and seal pressure before leaving factory.

5. Epoxy painting,thickness 250 μ m.