FEATURES

Suitable medium:Water, steam, oil, etc

Application:Water treatment, petrochemical, food and medicine, power energy, metallurgy, etc

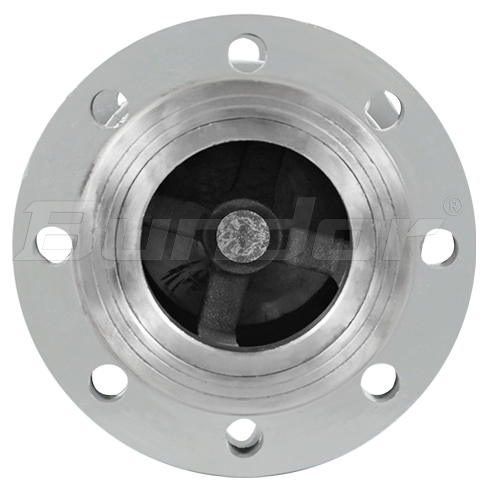

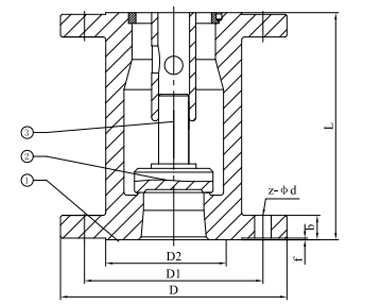

Product Identification:

The vertical type check valve is a check valve in which the valve disc rises and falls vertically along the valve body. When the medium flows downstream, the valve disc is opened by the thrust of the medium. When the medium stops flowing, the valve disc lands on the valve seat to prevent the medium from flowing backward. Function, the vertical type check valve should be installed on the vertical pipeline; it is widely used in pipelines in various working conditions such as water treatment, petroleum, ch

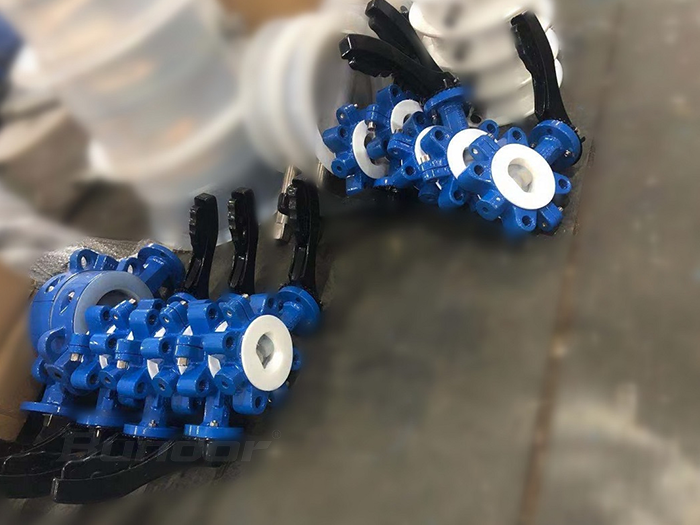

Product Advantages:

1. The valve body is a precision casting valve body, the material WCB meets the standard, the appearance is fine, and there is no trachoma

2. The internal parts are processed by CNC machine tools, and the appearance is processed by shot blasting twice, and the appearance is smooth and beautiful

3. The valve seat is surfacing welded with CR stainless steel to increase the wear resistance of the valve seat

4. Each valve leaves the factory in accordance with national standards for shell and seal double-layer pressure testing

5. Spraying with epoxy resin, the spraying thickness reaches 250μm