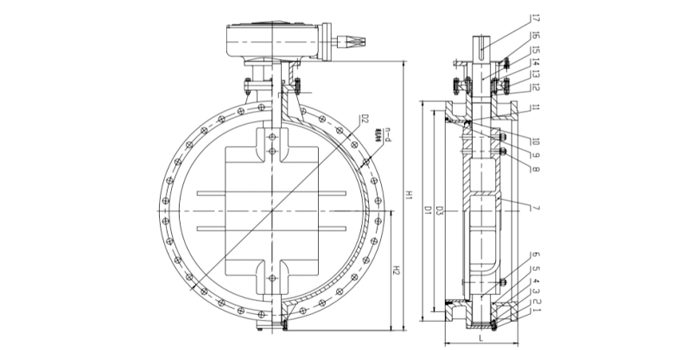

The structural feature of the double eccentric butterfly valve is that the shaft center of the valve stem deviates from the center of the butterfly plate and the center of the body. The double eccentric effect enables the butterfly plate to be released from the valve seat immediately after the valve is opened, which greatly eliminates unnecessary excessive extrusion and scratching of the butterfly plate and the valve seat, reduces the opening resistance, reduces wear and improves The life of the valve seat is improved. The scraping is greatly reduced, and at the same time, the double eccentric butterfly valve can also use a metal seat, which improves the application of the butterfly valve in the high temperature field.

Features:

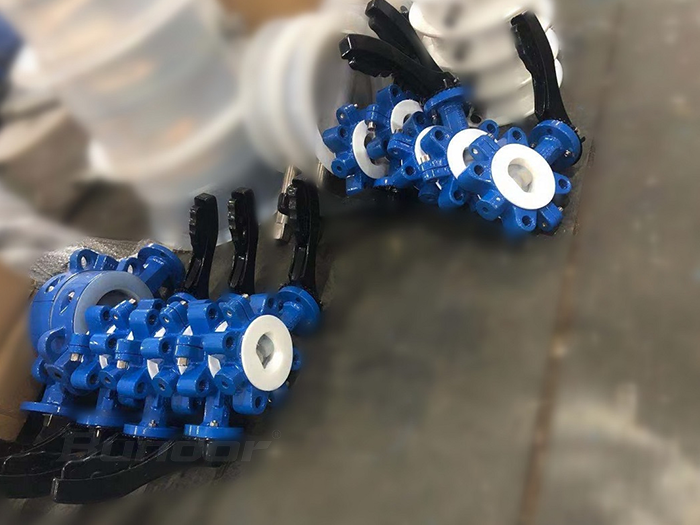

Applicable medium:Water, gas, oil, etc

Suitable temperature:0℃~80℃

Application field:Water treatment, municipal construction, drainage, power plants, etc.

Product advantages:

1. The body material is QT450 or WCB, and the chemical composition and mechanical properties meet the requirements of national standards. Material reports can be provided.

2. The valve body and inner parts are processed by CNC precision machine with high precision.

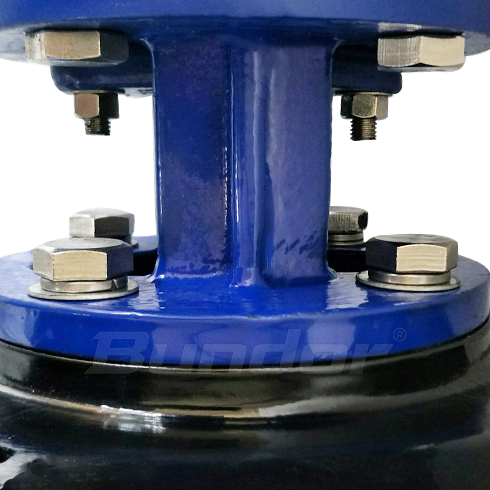

3. Adopt body sealing structure, which is different from the conventional plate sealing structure in the market, and can realize two-way sealing.

4. There are rubber soft seals and stainless steel hard seals available. The valve plate and other parts can also be selected according to the working conditions.

5. The valve seat is welded with stainless steel, which is more wear-resistant and has a longer service life.

6. The valve shaft is supported by self-lubricating sleeve bearings, which can reduce the friction produced during valve shaft transmission and reduce torque.

7. The world-famous brand Aksu epoxy resin spraying is used, and the spraying thickness is 250um.

8. Each valve must be tested in accordance with national standards when leaving the factory, and unqualified products will never