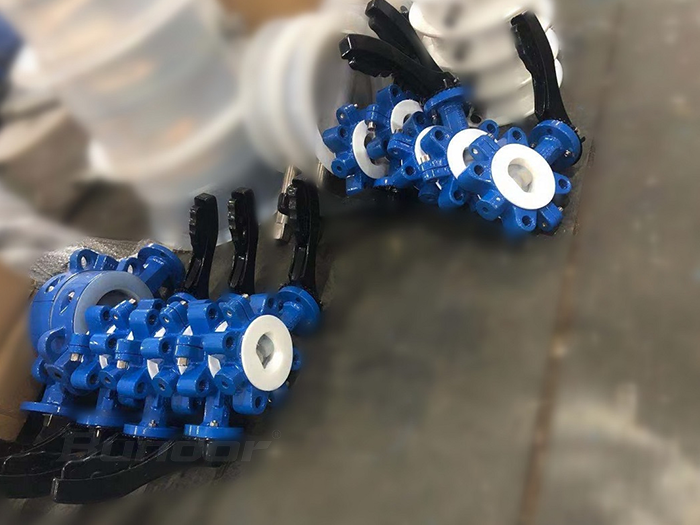

Electricity, construction, environmental protection, water treatment, water supply and drainage, etc.

Product advantages:

1. QT450-10 ductile iron body, 3 levels spheroidization rate, the tensile strength is 450MPa, the extension rate is over 10%. It is not easy to crack and freeze crack.

2. Epoxy coating for both valve inside and outside. Over 250μm coating thickness. Effectively prevent valve body corrosion and rust. It can be used in sewage system.

3. 50% rubber content EPDM coated DI wedge. The rubber is firmly coated with wedge, which is not easy to fall off.

4. 2Cr13 valve stem. Three O-ring sealing design. Reduce frictional resistance when switching, avoid medium exposure.

5. Brass stem nut and positioning device, switch smoother and avoids jamming during operation.

6. IP65 protection level electric actuator .