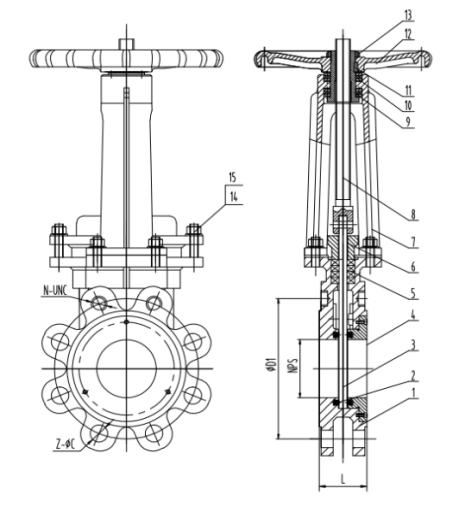

Knife gate valve is also known as knife gate valve, slurry valve, mud valve. Its opening and closing parts are gate. The movement direction of gate is perpendicular to the direction of the fluid. Depending on cutting fiber material blade shaped gate to cut off the medium. The gate board rises and falls in the side guide groove and is pressed on the seat by the bottom lug. If high medium sealing is needed, o-type sealing seat can be selected to achieve two-way sealing. Knife gate valves have small installation space, low working pressure, long service life, simple maintenance.

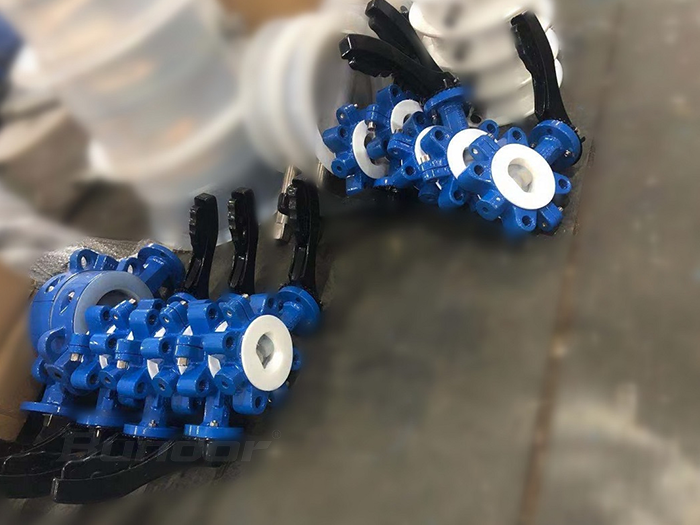

Suitable Medium:Water, mud, ash, slag and water mixture, etc.

Working Temperature: 0~80℃.

Application field:Coal mine, chemical industry, environmental protection, water treatment, water supply and drainage, etc.

Product Advantages

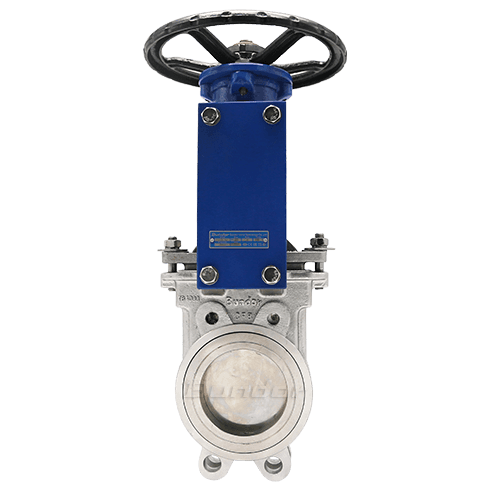

1. Precision casting valve body, fine appearance, no sand hole, traceable with Heat number.

2. Valve wedge is burnished smoothly 3 times and polished 5 times to ensure the sealing porformance.

3. Valve stem is equipped with bearing to reduce friction, increased service life.

4. Add steel wire to seat ring to ensure the strong conbation between valve seat and body.

5. 250 μm epoxy coating, it can effectively prevent corrosion and rust.

6. Each valve will be made pressure test before leaving factory.

.jpg)

.jpg)

.jpg)