Features:

Suitable medium:Water, weak corrosive medium, etc.

Application : Water treatment, petrochemical, food and medicine, electric energy, metallurgy, etc.

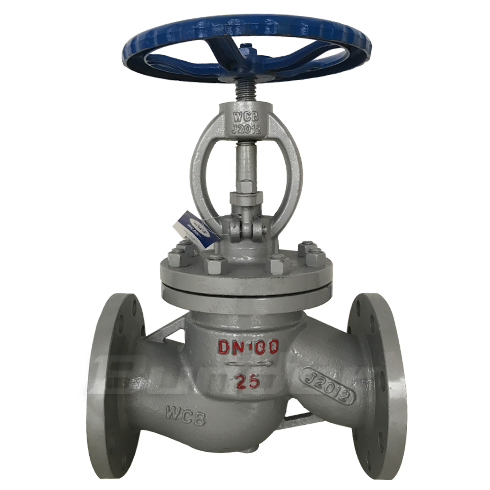

Product Identification:

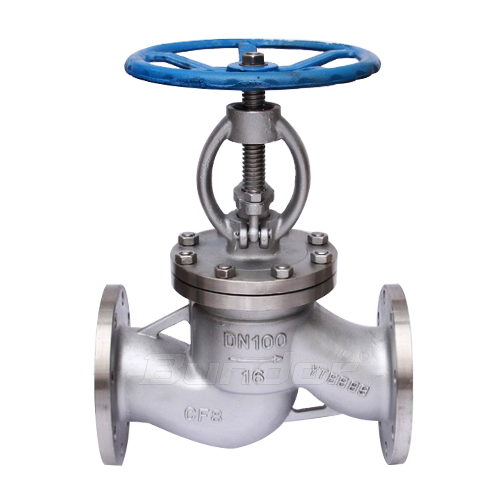

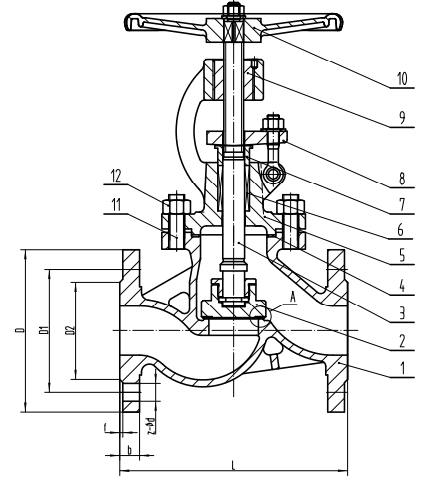

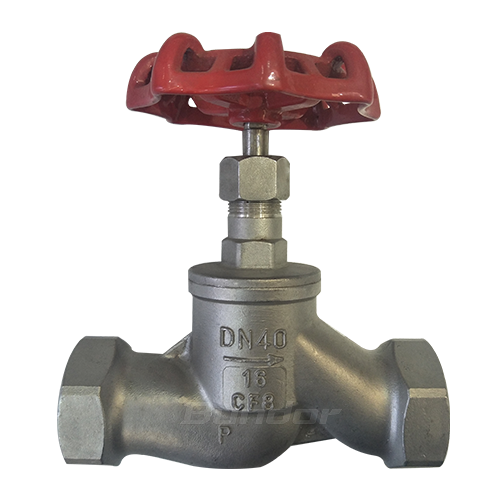

The axis of the valve stem is perpendicular to the sealing surface of the valve seat, the stem is opened or closed very fast, which makes the valve is very suitable for cutting off or regulating the medium; The valve body is 304, 316 etc. It widely used in chemical, shipping, medicine, food machinery and other industries.

Product Advantages:

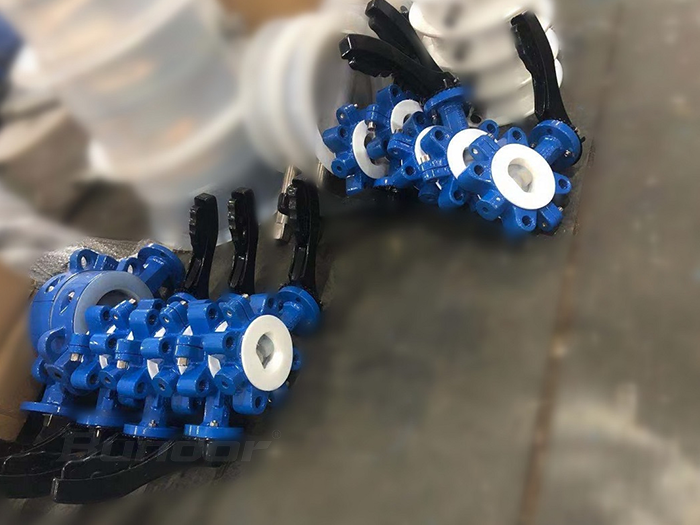

1. Precision casting valve body,2 shot blasting treatment,smooth appearance, no trachoma.

2. CNC lathe processing of internal parts

3. Heavy type valve body.

4. Inverted seal treatment of contact surface between bonnet and stem to avoid leakage.

5. Each valve body is pickled and passivated to make the casting uniform and bright and improve corrosion resistance

6. Each valve will be inspected for shell and seal pressure before leaving factory.