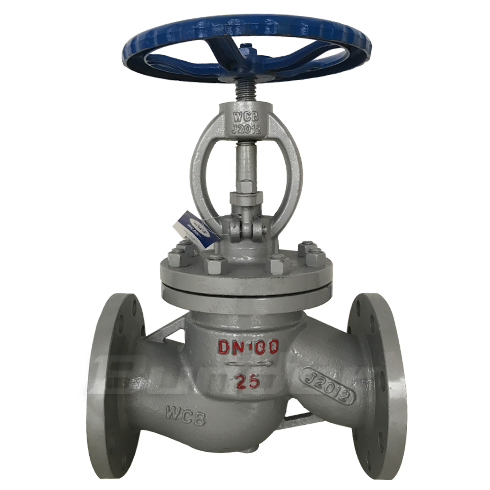

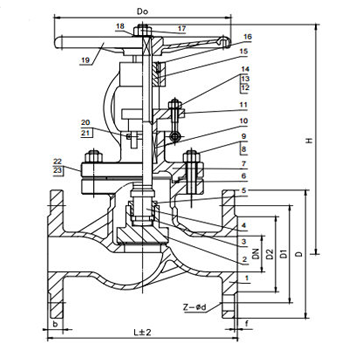

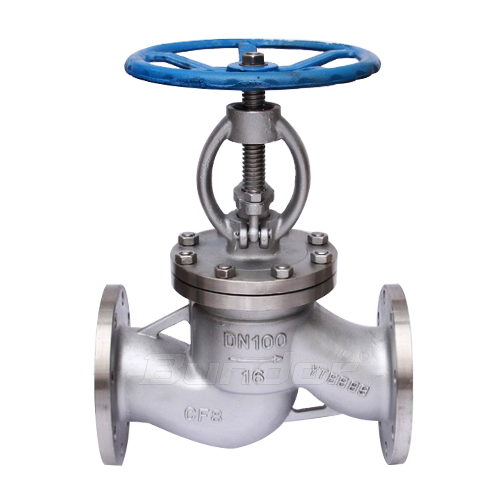

Product introduction

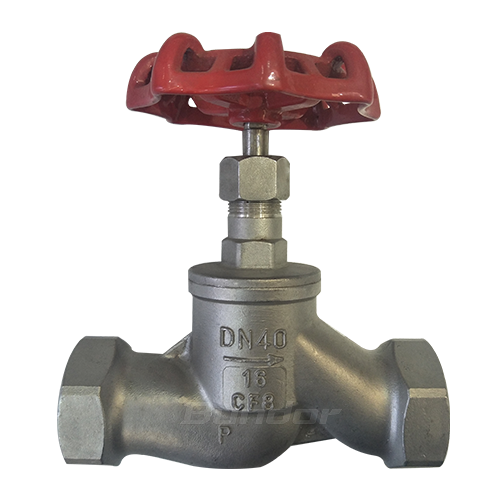

Flange connected valve applicable to nominal pressure PN1.6~PN4.0Mpa, roommate working temperature -29~425 DEG C, chemical, pharmaceutical, chemical fertilizer, the power industry and condition of the pipeline, cut off or connected to medium, suitable for water, oil, steam, acid medium, and the operation mode: manual, gear, electric, pneumatic, etc.

Adoptive Standards

Body Test: 1.5 times the working pressure with water. This test is performed after valve assembly and with disc in half position open, it is called as a body hydro test.

Seat Test: 1.1 times the working pressure with water.

Function / Operation Test: At the time of final inspection, each valve and its actuator (Flow-Control Lever / Gear / Pneumatic Actuator), under goes a complete operating test (Open/Close). This test carried out without pressure and at ambient temperature. It ensures the correct operation of the valve / actuator assembly with accessories such as solenoid valve, limit switches, air filter regulator etc.

Special Test: On request, any other test can be carried out according to special instruction by client.

Product Advantage

1.The sealing surface has the advantages of good sealing performance, easy operation, no damage to the sealing surface, long service life and no water hammer phenomenon.

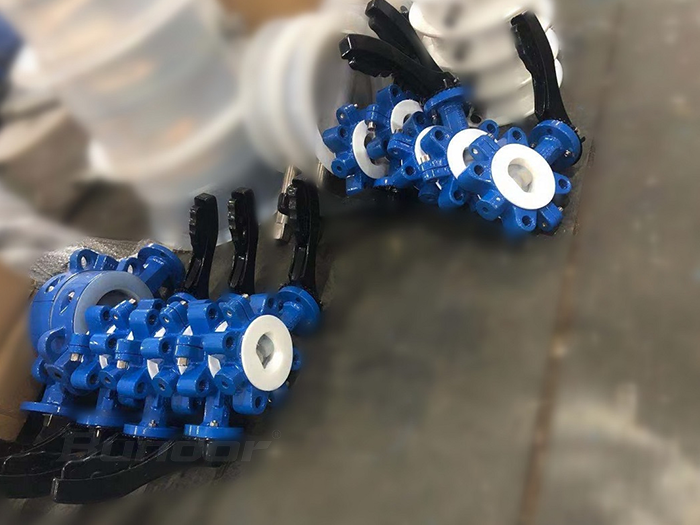

2.The product has reasonable structure, reliable sealing, excellent performance and beautiful appearance.

3.Stem after the modulation and surface nit riding treatment, has a good corrosion resistance and abrasion resistance.

4.The product can be used with standard pipe flanges and flange sealing surface in the form, to meet the needs of various projects and user requirements.

Standard Test

Valve design and manufacture according to GB/T12237-1989

Valve test according to GB/T13927-1992