Features:

Size: DN15-DN600

Pressure: 150LB

Working temperature:-10~200°C

Suitable medium: Water, Oil

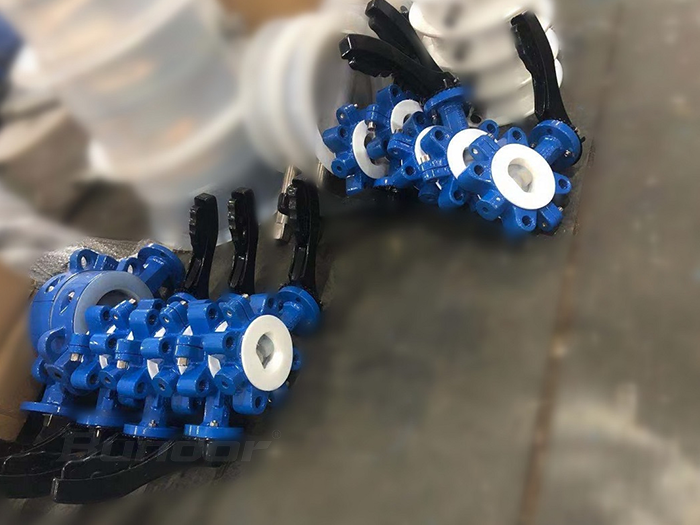

Body: DI

Application: Municipal construction, water project,electricity,water supply and drainage,water treatment,petroleum

Advantages:

1、1.The body is ductile iron,high level than national stanard.Tensile strength is 450Mpa,elongation is large than 10%,can not be broken easily when transport.

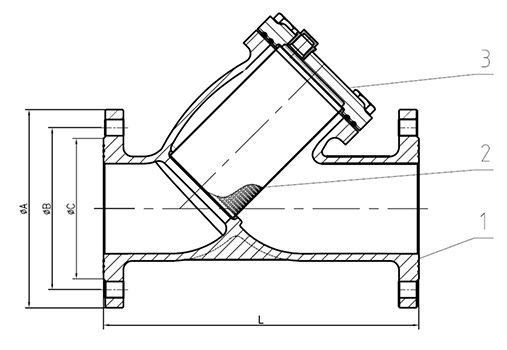

2、The screen adopts 304 steel plate punching, rolling, spot welding, mesh mesh can be customized according to customer requirements, DN200 and above size with reinforcement structure design, high strength of the screen, with erosion resistance, corrosion resistance characteristics, the material of the screen through the spectrometer strict detection, ensure that the chemical composition of the screen meets the standard requirements.

3、Sealing gasket made of graphite material, high temperature resistance, long service life

4、The strainer adopts full size form and streamline design to reduce the fluid resistance coefficient of the strainer.The diameter and length of the screen increase, increase the effective filtration area of the screen, reduce the pressure loss

5、The valve cavity becomes larger, and the circulation area between the screen and the inner wall of the valve body is more than half of the flow channel area, which effectively improves the utilization rate of the mesh at the back of the screen and reduces the pressure loss.

6、The location of the drain hole in the low end of the valve cover makes the drain more thorough and improves the efficiency of the drain.

7、Both inner and out part is epoxy coating, the thickness is 250μm minimum,can prevent rust well,can be used in sewage system.