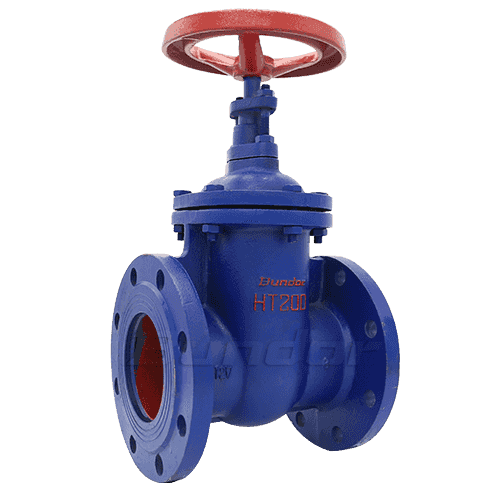

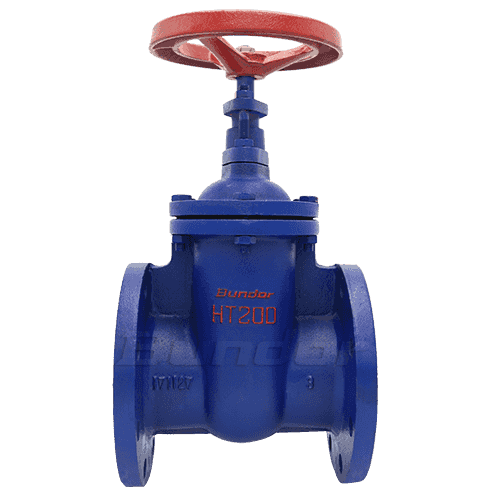

Product Features:

Low torque operation

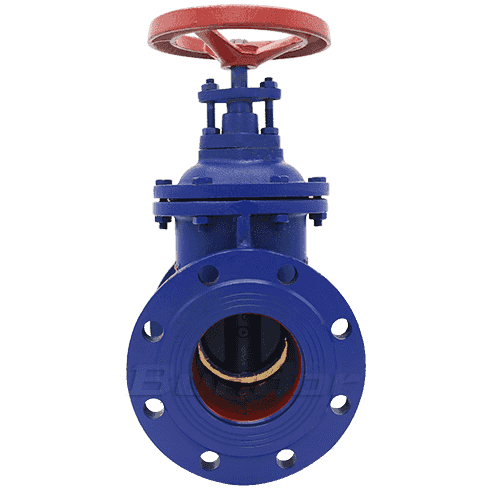

Rubber encapsulated wedge

Clockwise closing direction

Fusion bonded epoxy coated inside and outside

Advantage:

1.Cast iron body adopts HT200, executes GB/T12229-2005 tensile strength 180~210Mpa.

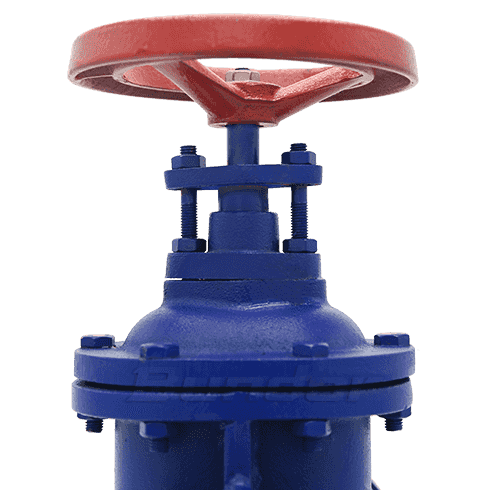

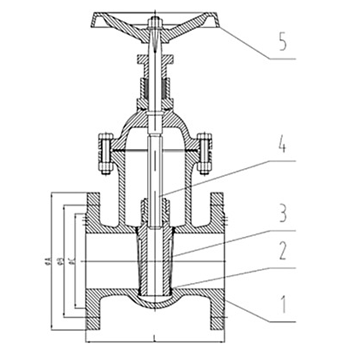

2.Bonnet material adopts HT200,same as body material, its wall thickness in accordance with the requirements of GB, EN standards, in accordance with the requirements of API standards, with a sealed seat; if the bonnet was stainless steel material, the upper seal seat wil be one an indivisible whole.

3.The design of T stem processing with spherical head , make contact with the gate size is more reliable; according to the API standard, its surface roughness grinding must reach Ra0.8 μm, to reduce the operating friction resistance and to prevent leakage of filler.

4.Stem nut according to API standard material A493-D2, QT450-10, if stainless steel, its material is bronze.

5.The standard for body ,bonnet and bolts shall be full tooth bolts, in accordance with the specifications of API, and shall be fitted with heavy nuts, whose bolts / nuts shall be manufactured in strict accordance with the specifications of ASME, B1.1, ASME, B18.2.2.

6.The valve seat is made of QT450 material, and the aluminum bronze and the wedge face have different hardness. Stainless steel valve seat as a whole, and can be welded with special carbide according to requirements.

7.Using a flexible wedge chip design of casting, processed to make track and valve body with a smooth operation, the seat sealing surface by polishing processing, the surface roughness can reach a maximum mirror, to reduce and prevent leakage of occlusion. Sealing surface welding special carbide can be custom made.

8.The wall thickness of the valve is in accordance with GB and EN standards. The body and bonnet adopt a concave convex groove ,close fit to ensure the concentricity of the body and bonnet and reduce the frictional resistance and torque during operation.

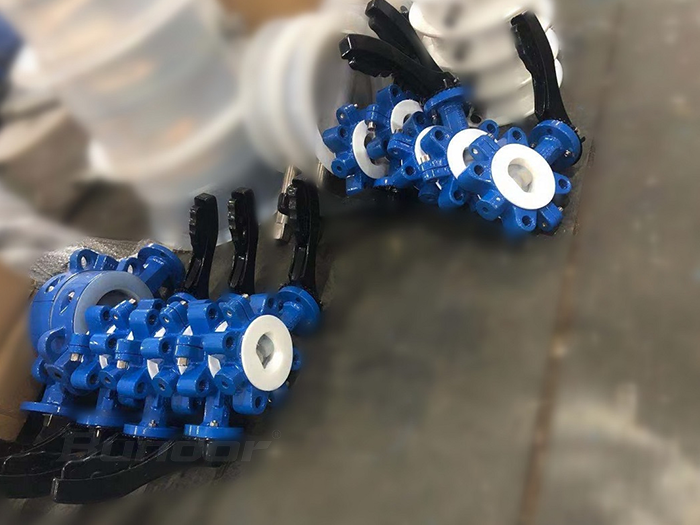

9.Each product will be carried out appearance, material, air tightness, pressure and shell testing before leaving the factory ;unqualified products are resolutely not allowed to leave the factory.

10.Bundor company specialized intentions since 1994, has a professional production, sales, research, after-sales team, is your strong backing of sales and use.