The centerline butterfly valve is usually used for water supply and drainage and gas pipelines with temperature ≤120℃ and nominal pressure ≤1.6MPa for food, medicine, chemical industry, petroleum, electric power, textile, papermaking, etc. to adjust flow and cut off fluid.

Advantages of centerline butterfly valve

- The channel is designed as a full-diameter structure, which ensures the flow area of the valve and reduces the flow resistance when the fluid passes through the valve.

- The disc is designed with a disc-shaped streamline, which can not only ensure the stress intensity in the center of the disc, but also ensure that the valve can obtain a larger flow coefficient and a smaller fluid resistance coefficient.

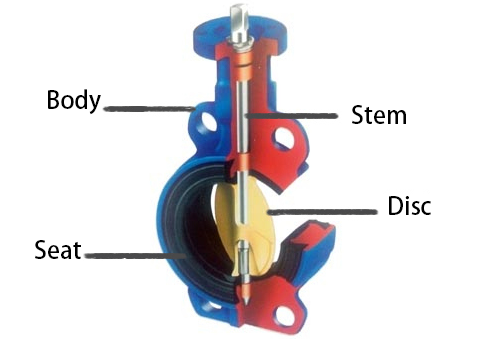

- The valve seat sealing ring is designed as a soft sealing structure of rubber and resin skeleton (fixed sleeve), which is embedded in the valve body after being made. The part of the inner ring higher than the inner cavity of the valve body adopts a streamlined design to achieve the purpose of reducing the flow resistance.

- The operating torque of the butterfly valve is small, the operation is convenient, labor-saving and smart.

- It can be installed in any position and easy to maintain.

- The seals can be replaced, and the sealing performance is reliable to achieve zero leakage of bidirectional sealing.

- Under normal temperature and pressure, the sealing material is resistant to aging and corrosion, and has a long service life.