Working temperature:0~80℃

Application:Food, medicine, chemical industry, environmental protection, water treatment, water supply and drainage

Product Identification:

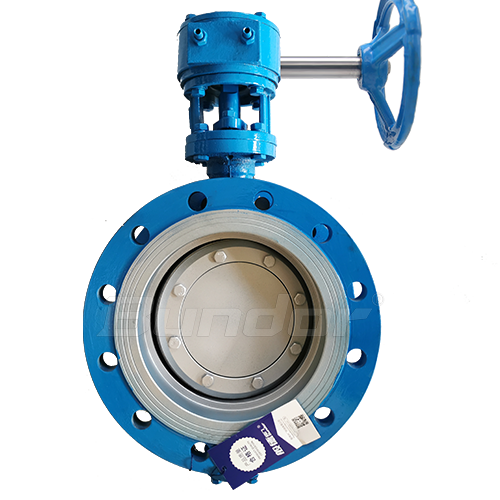

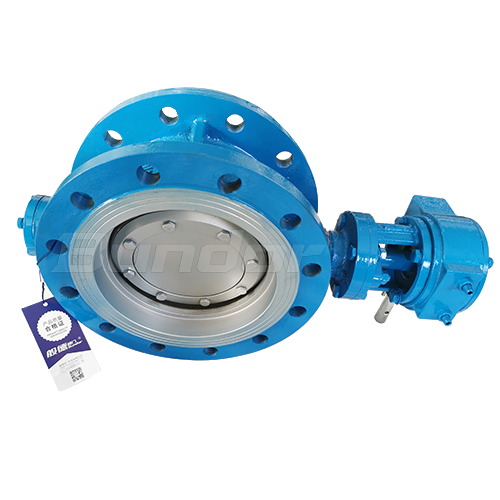

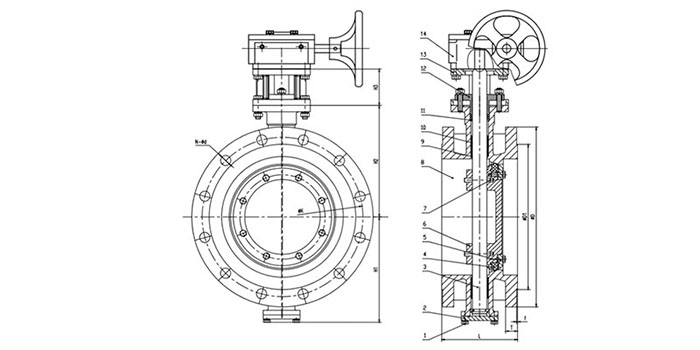

Double eccentric butterfly valve is further improved on the basis of single eccentric butterfly valve.The structure is characterized by that the valve stem axis deviates from both the disc center and the body center.Double eccentric effect enables the butterfly plate to leave the seat immediately after the valve is opened, greatly eliminating unnecessary excessive squeezing and scraping between the butterfly plate and the seat, reducing the opening resistance distance, reducing wear and increasing the life of the seat.

Double eccentric butterfly valve is mainly used in water works, power plants, steel smelting, chemical engineering, water source engineering, environmental facilities construction and other systems for drainage.Compared with the center line butterfly valve, double eccentric butterfly valve is more resistant to high pressure, longer life and better stability.

Product Advantages:

1. Precision casting valve body. Qualified WCB material. Fine appearance, no sand hole.

2. Heavy valve body. Wall thickness meets the requirements of GB26640 to ensure compressive strength.

3. The valve body and inner parts are processed by CNC precision machine with high precision.

4. Different sealing materials can be selected to ensure the sealing surface wear resistance, erosion resistance, corrosion resistance, long service life.

5. Replaceable disc seal ring can be easily replaced.

6. The valve shaft is supported by self-lubricating sleeve bearings, which can reduce the friction produced during valve shaft transmission and reduce torque.

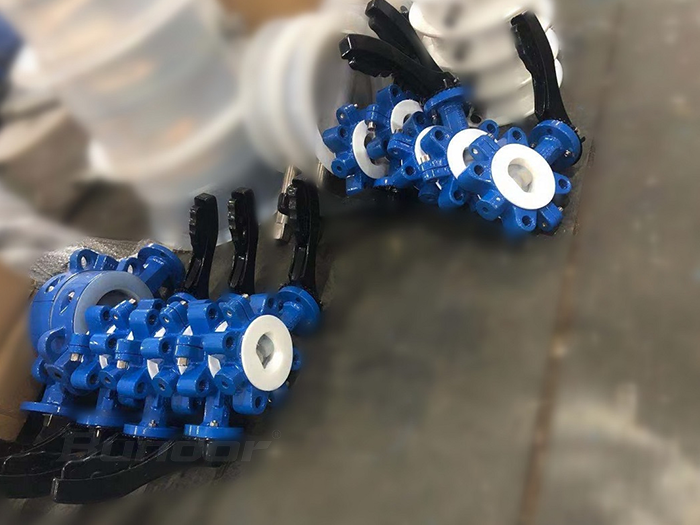

7. Each valve will be inspected for shell and seal pressure before leaving factory.

8. Epoxy coating, beautiful apperance.