Applicable medium:Gas, dust gas, flue gas, etc.

Suitable temperature:-29~425℃

Application field:Environmental protection, metallurgy, chemical industry, electric power, building materials, etc.

Product advantages:

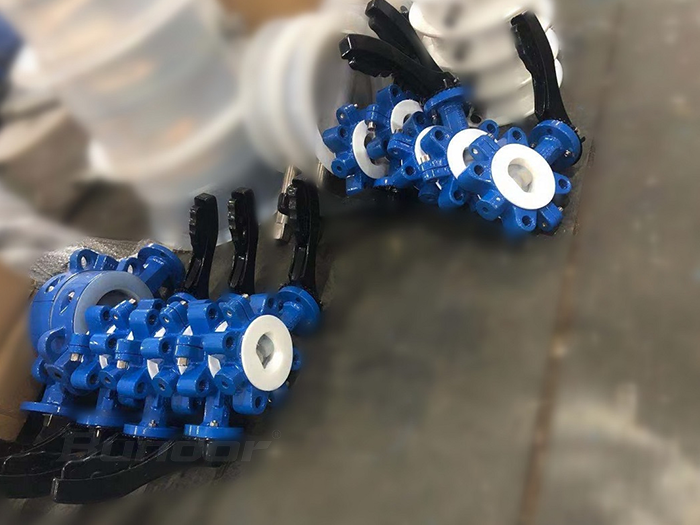

1. Precision casting valve body. Qualified WCB material. Fine appearance, no sand hole.

2. Heavy valve body.

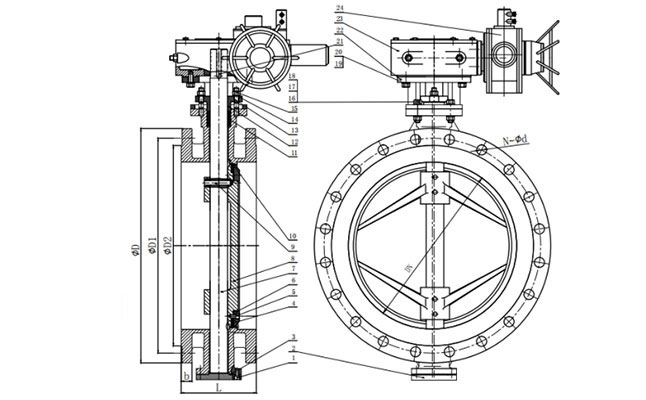

3. The valve disc is processed by CNC precision machine with high precision.

4. The sealing ring of the valve body adopts soft and hard multi-layer metal ring, which has the double advantages of metal and elastic seal, to ensure excellent sealing performance in high temperature and low temperature environment.

5. Shaft made of stainless steel, through special treatment to double the strength of the shaft.

6. Each valve will be inspected for shell and seal pressure before leaving factory.

7. The protection level of electric actuator reaches IP65.