Features:

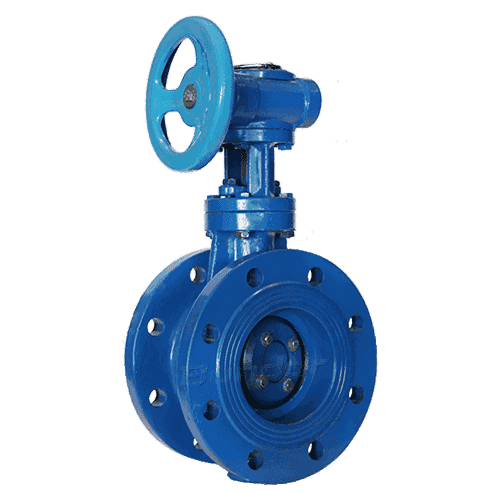

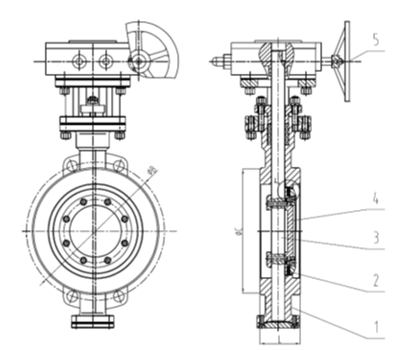

Three Eccentric Design

Stainless Steel sealing, good sealing performance with both low temperature and high temperature, anti-corrosive, long life

Sealing seat anti-frictional and long life

Bi-Directional

Fire safe Design

Low Friction Body Seat

Product Advantages:

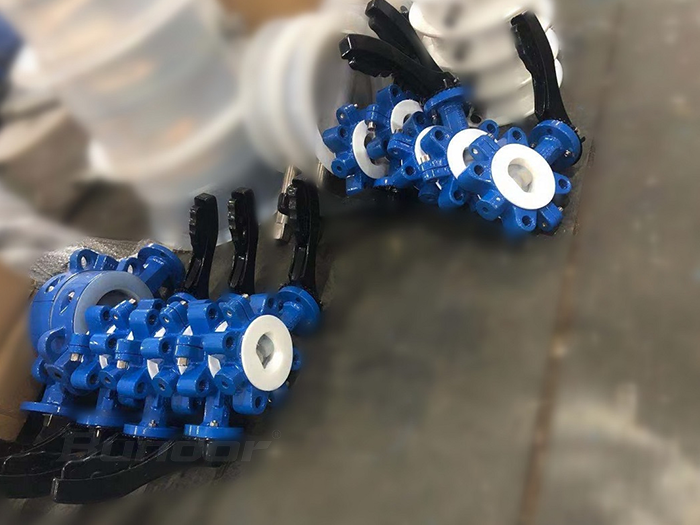

1. The valve body is all precision cast valve body. The material of WCB is up to standard and the appearance is fine.There is no trachoma and every batch of casting has furnace number sign,which is convenient for production tracking and material protection inspection.

2. The valve body adopts ZG250-485 material that conforms to the national standard, and it undergoes 15 processes from the original iron to the valve body.

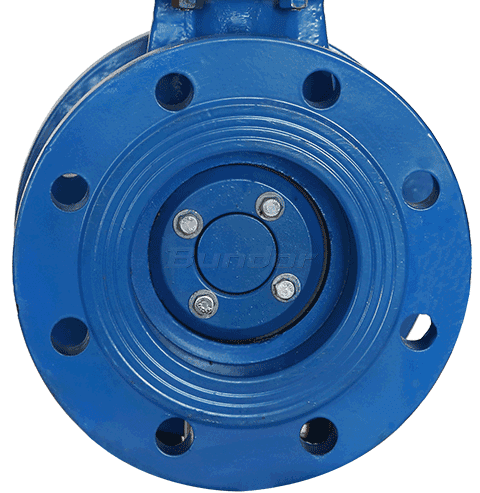

3. The CNC lathe processing butterfly plate, the sealing ring is a soft and hard multi-layered metal ring, with the dual advantages of metal and elastic seal, to ensure excellent sealing performance in high temperature and low temperature environment.

4. The valve stem is made of stainless steel. After quenching and tempering, the strength of the valve stem is doubled, which reduces the problem of opening and closing and leakage caused by deformation of the valve stem.

5. After the production of finished products, each product shall be coated with lead-free paint three times for the primer and topcoat to ensure the brightness and rust resistance of the product's appearance.

6. After the product is pressured and adjusted, the turbine adjusting screw is processed again, and the lengths of the products are adjusted to be consistent. The turbine adjusting screws of each product are equipped with protective nuts to protect the adjusting screws from damage.

7. The valve plate is heavy, the valve stem is thick, the pin is large, the valve seat is processed with fineness, flatness, and no welding bead.

8. The quality inspection from the blank to the packaging of finished product.

9. Bundor brand products are covered by the China Pacific Insurance with 10 million dollars,2 years warranty, pay two back if one bad,any quality problem of the product itself, we will pay without conditions.

Adoptive Standards:

Valve Design: API 609, MSS SP-67

Face To Face: API 609, MSS SP-67, DIN3202, BS EN558-1

Pressure Test: API 598

Flange Drilling: ANSI B16.1 class125, BS4504 PN10/PN16, DIN2501 PN10/PN16

Top Flange: ISO5211

Standard Test :

Body Test: 1.5 times the working pressure with water. This test is performed after valve assembly and with disc in half position open, it is called as a body hydro test.

Seat Test: 1.1 times the working pressure with water.

Function / Operation Test: At the time of final inspection, each valve and its actuator (Flow-Control Lever / Gear / Pneumatic Actuator), under goes a complete operating test (Open/Close). This test carried out without pressure and at ambient temperature. It ensures the correct operation of the valve / actuator assembly with accessories such as solenoid valve, limit switches, air filter regulator etc.

Special Test: On request, any other test can be carried out according to special instruction by client.