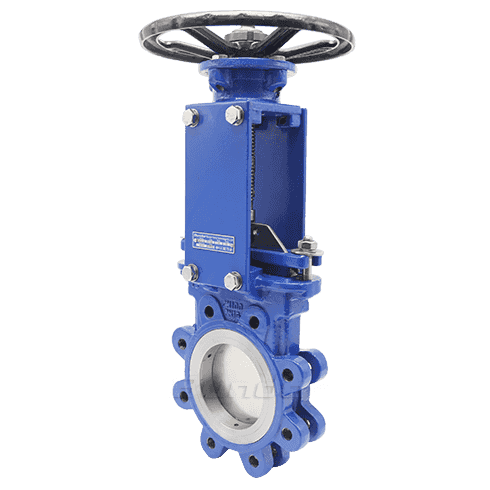

Features:

Medium used: syrup, pulp, sewage, coal slurry, ash, slag water mixture.

Suitable temperature:below 80 degrees Celsius

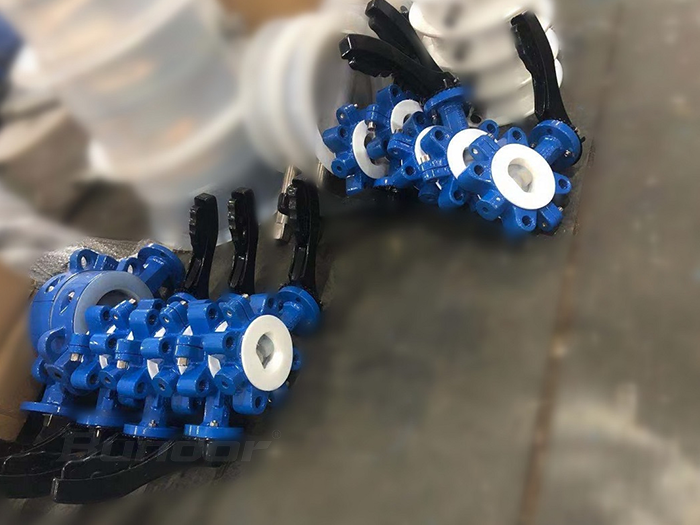

Application field:municipal construction, water treatment, power, water supply and drainage, water conservancy projects.

Product advantages:

1.Stainless steel parts

The inner parts are made of stainless steel to ensure the purity of the medium.

2.Long service life

It overcomes the defect that the traditional valve is easy to rust and corrode, and extends the service life.

3.Reliable, hygienic and anti-corrosion

The inner and outer surface of valve body, cover, battening and connecting plate is sprayed with epoxy resin.

4.Good performance

valve stem material is stainless steel, the valve stem thread is rolled, the performance is excellent.

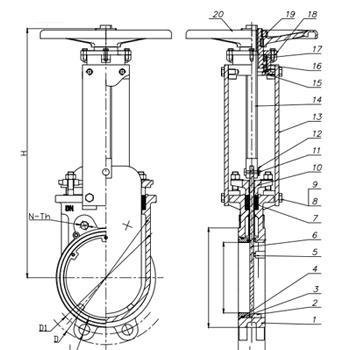

5.Simple and compact structure

It is characterized by simple and compact structure, reasonable design, reliable sealing, lightweight material and flexible operation.

6.Easy to install and disassemble

Small volume, smooth passage, small flow resistance, light weight, easy to install, easy to disassemble