Applicable medium:Water, weak acid and alkali, air, steam, oil, etc.

Suitable temperature:0 degrees Celsius to 150 degrees Celsius

Application field: Municipal construction, chemical industry, water treatment, electricity, petroleum, water supply and drainage, water conservancy projects.

Product advantages:

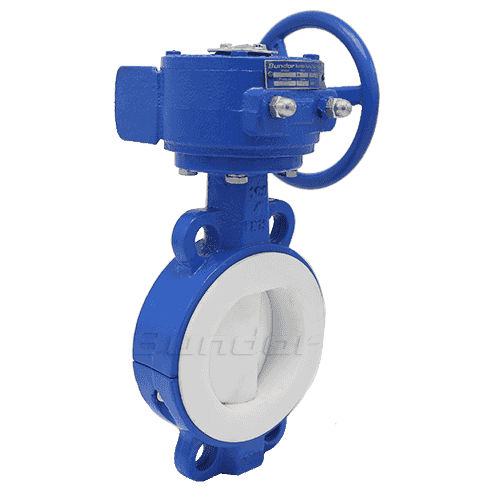

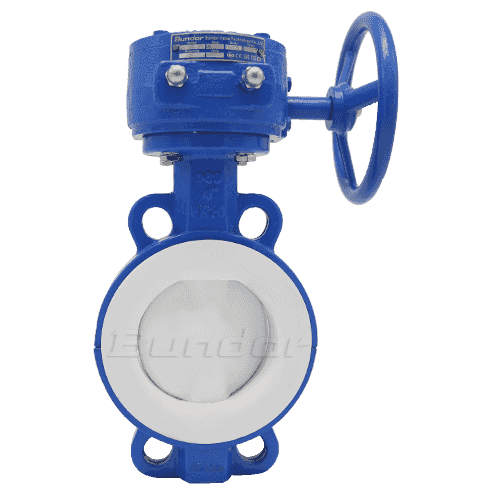

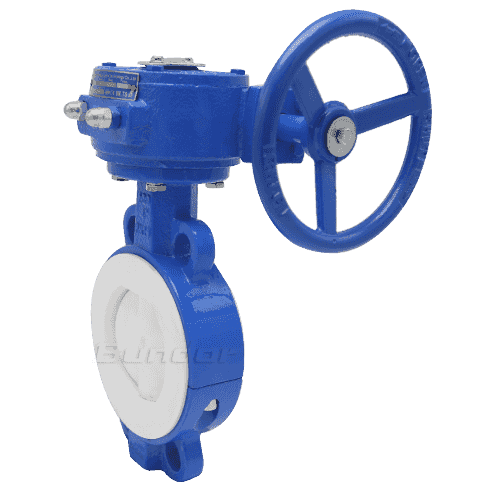

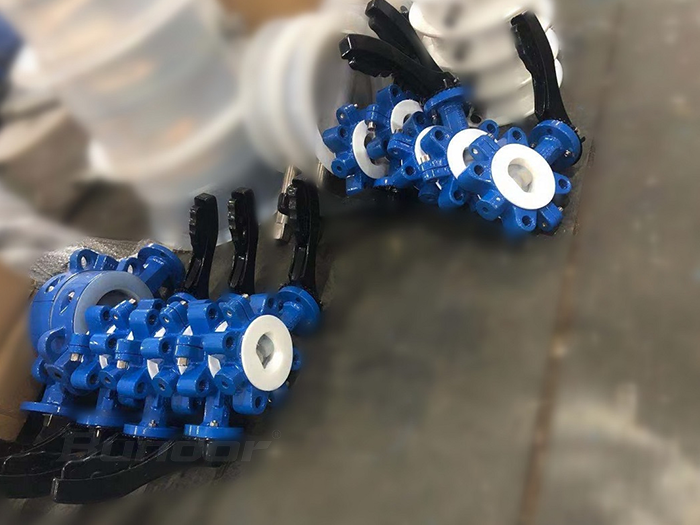

1. Precision casting valve body with fine appearance

All the valve body is made of WCB material with fine appearance. Each batch of casting has a specific number to facilitate production tracking and quality inspection.

2. The seat is reprocessed and shaped, with good sealing performance

PTFE seat is machined into shape after integral die casting to ensure density and tightness.

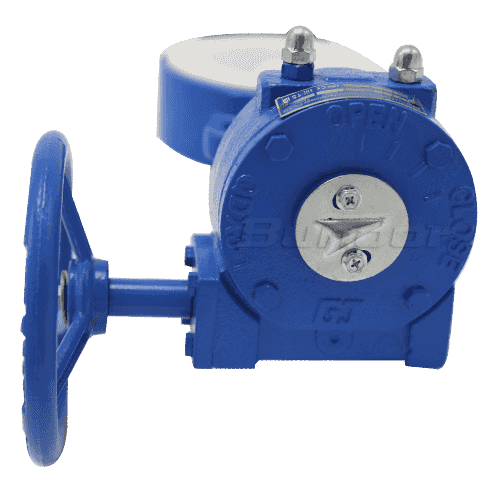

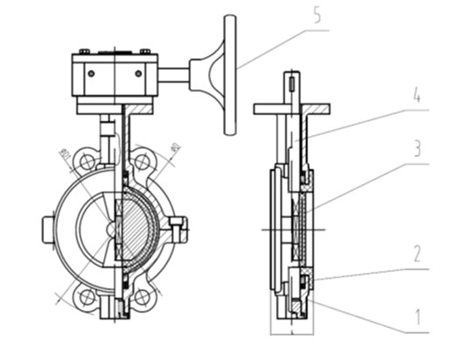

3. Double seal to avoid leakage

Double sealing ring is used on both sides of valve shaft to avoid leakage at valve shaft.

4. Special process painting, effective anti-corrosion

The valve body is electrostatic coated with powder epoxy resin, which can effectively prevent corrosion and rust caused by the contact between the valve body and the medium, and can be used in the sewage system.

5. Select raw materials with reliable quality

All raw materials of PTFE adopt domestic first-line brands.

6. Repeated quality inspection to ensure product quality

From parts and parts to finished packaging factory each link strict quality control.

7.Two years warranty, pay two back if one bad

The products of Bundor are insured by the Pacific insurance company with 10 million quality, and the quality is guaranteed for two years.