Features:

24 months guarantee

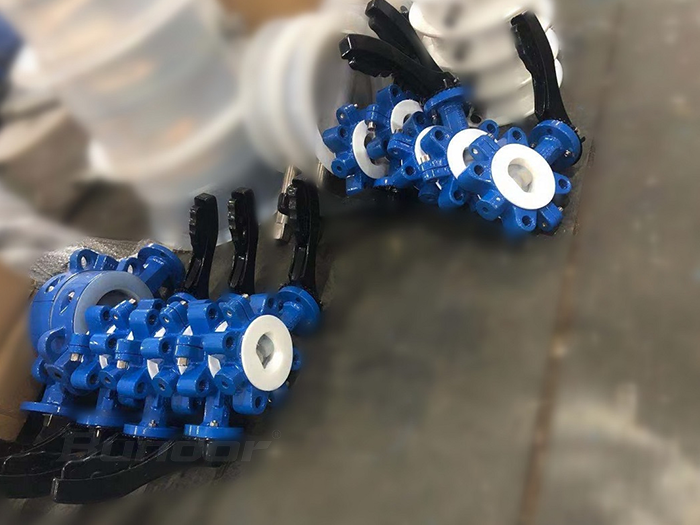

Zero Leakage

Bi-Directional

Low Torque,long life cycle

360°polished disc assures positive on-off

Epoxy coated body,smooth surface

Various kinds of materials,applicable to different medium

Adoptive Standards

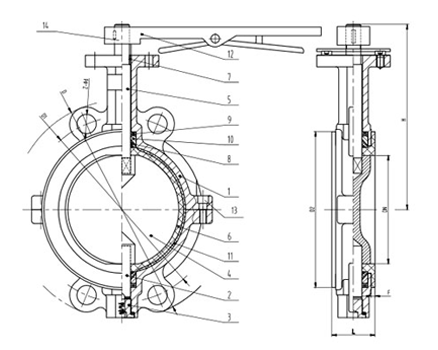

Valve Design: API 609, MSS SP-67

Face To Face: API 609, MSS SP-67, DIN3202, BS EN558-1

Pressure Test: API 598

Flange Drilling: ANSI B16.1 class125, BS4504 PN10/PN16, DIN2501 PN10/PN16

Top Flange: ISO5211

Product Advantage

1.The length of the short structure can save raw materials and installation space, and also effectively support the strength of the pipeline

2.The valve block is the correct movement of the gate, extrusion fast, to ensure effective sealing valve

3.Triangle support material, guarantee the required mechanical properties

4.According to different working conditions demand design V, triangle, or five corners and other ports, in order to meet the needs of various flow regulation

5.No groove at the bottom to make sure no slag and full bore flow

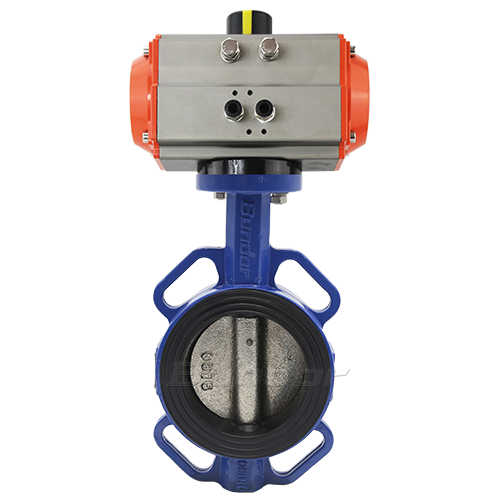

6.Bundor valve strict implementation of the API598 experimental standard, for each product to implement 100% positive and negative double pressure test, guarantee delivery to customers is 100% qualified products

7.Bundor Group dedicated to the dedication of the valve for 23 years, with professional production, sales, research and after-sales team,we are your strong backing.

Standard Test

Body Test: 1.5 times the working pressure with water. This test is performed after valve assembly and with disc in half position open, it is called as a body hydro test.

Seat Test: 1.1 times the working pressure with water.

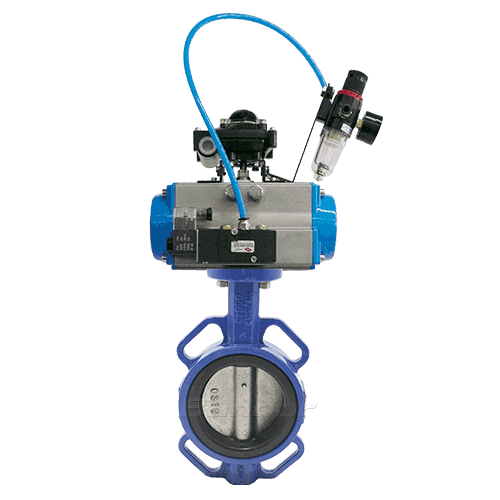

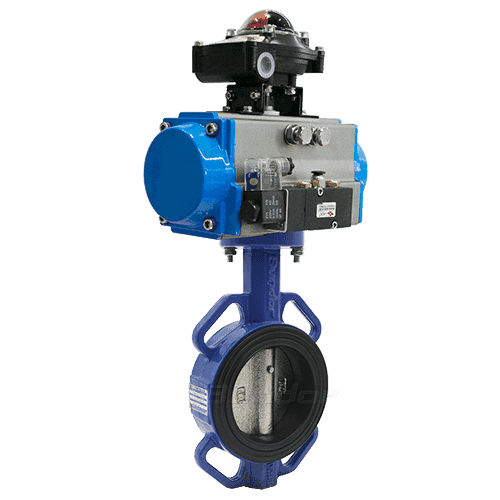

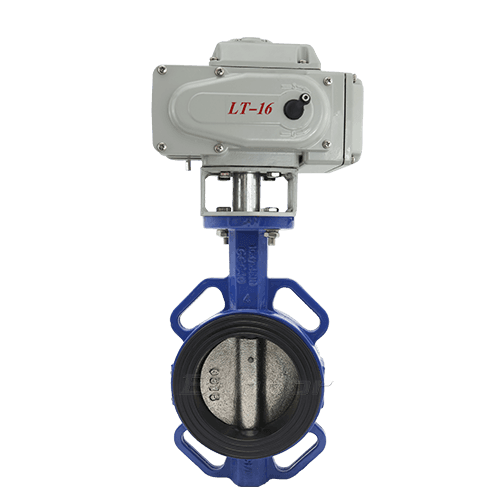

Function / Operation Test: At the time of final inspection, each valve and its actuator (Flow-Control Lever / Gear / Pneumatic Actuator), under goes a complete operating test (Open/Close). This test carried out without pressure and at ambient temperature. It ensures the correct operation of the valve / actuator assembly with accessories such as solenoid valve, limit switches, air filter regulator etc.

Special Test: On request, any other test can be carried out according to special instruction by client.