Features:

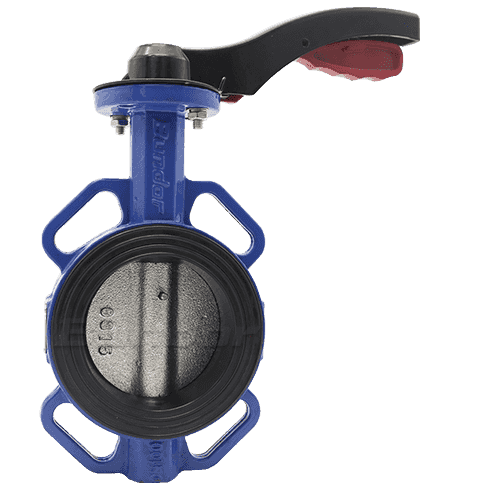

Applicable medium:Clear water and neutral liquid

Suitable temperature:- 20 ~ 120 ℃

Application field:Municipal construction, water conservancy projects, water supply and drainage, water treatment, etc

Product advantages:

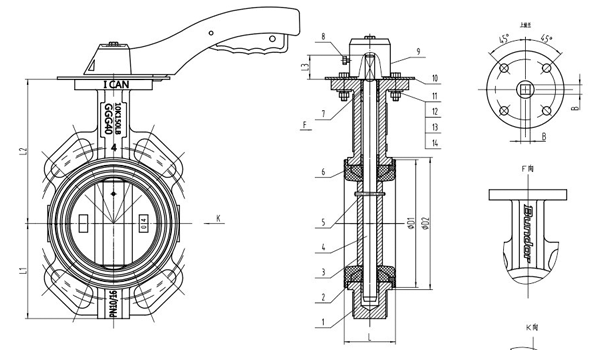

1. The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2. The thickness of valve body meets the requirement of GB 26640, and the thickness and pressure strength are guaranteed.

3. The valve body is made of qt450-10 material and has 3 grades of spheroidization rate, with stronger mechanical properties, tensile strength of 450Mpa and extension rate of more than 10%. Compared with cast iron body, the tensile strength of the same thickness is twice that of cast iron body, and the applicable working pressure is higher.

4. The seat is made of imported rubber material with 50% adhesive content.The valve sealing is reliable, the opening and closing moment is stable, the valve seat has a long service life, and the opening and closing times can reach more than 10000.

5. The seat is a wide-edge seat, which is favorable for valve installation, wide contact surface with flange boss on pipeline, reliable sealing performance, and the installation precision is lower than the narrow-edge seat. Seat axial with concave table, with o-ring, can realize seat axial secondary seal.

6. The valve shaft and valve body are equipped with 4 oil-free bearings and 3 o-type seals. The valve shaft supports more vigorously and the axial seal is more reliable.

7. Ultrasonic cleaning shall be carried out before packing of each valve, so as to prevent contamination and particulate impurities from remaining in the valve body, ensure cleanliness of the valve and prevent contamination of the water body of the pipeline by the valve itself.

8. The body is sprayed with epoxy resin plastic powder from Aksu, a world-famous brand, which can be deposited thicker and have stronger adhesion after melt curing.

9. On the packaging: each valve of Bundor is individually packed with PE heat-shrinkable film, with built-in drying agent to isolate air dust and prevent the valve from being polluted by damp.

10. The position of the sign table is humanized and set on both sides of the valve body. After installation, it is convenient for users to view.The sign is made of 304 material, with laser marking. The writing is clear and lasts for a long time.Fixed with stainless steel rivets, more beautiful appearance and stronger connection.

11. The bolt is made of 304 material, with stronger anti-rust ability.

12. The pin with the pin butterfly valve adopts the tempering treatment, with high strength and wear resistance, and the connection is safe and reliable.

13. Each product of Bundor has its own QR code mark and unique ID number from accessories to finished products.By scanning the codes, the inspection results of each stage in the production process can be inquired to achieve traceability of product quality.

14. All products of Bundor can provide material inspection report of main components.

15. As for the product of Bundor brand, it is insured by the Pacific insurance company with the quality of 10 million RMB, and the warranty lasts for 2 years. If the product is damaged within two years, it will be compensated for the unqualified because of the quality problem of the product itself.