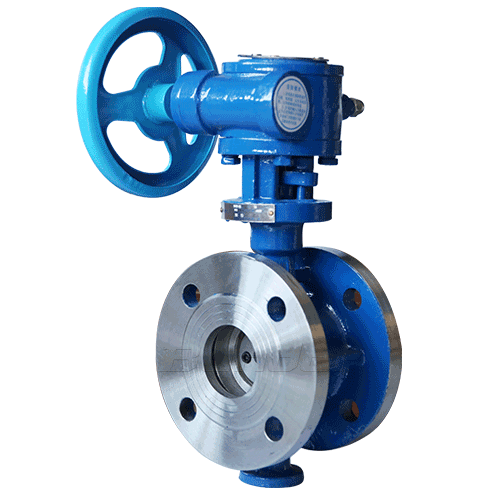

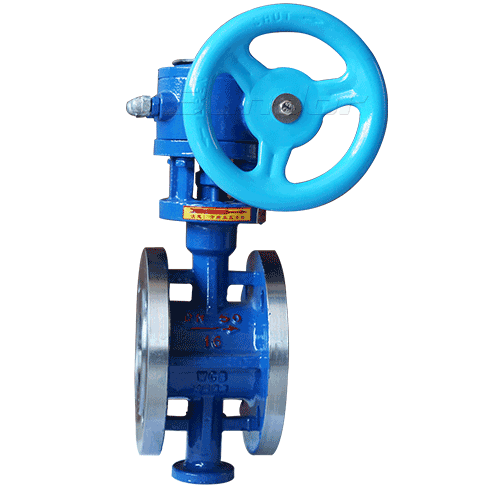

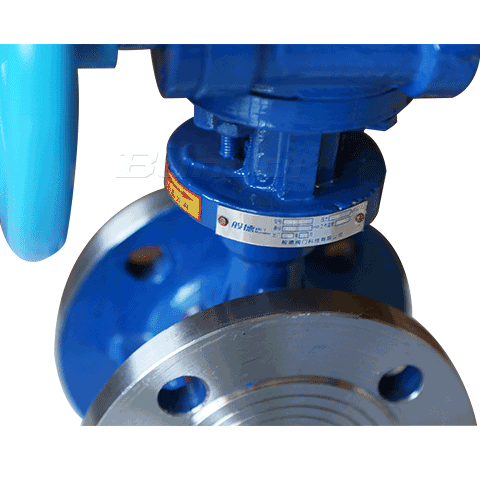

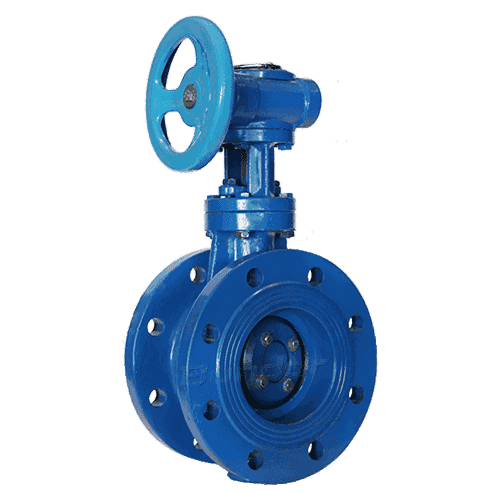

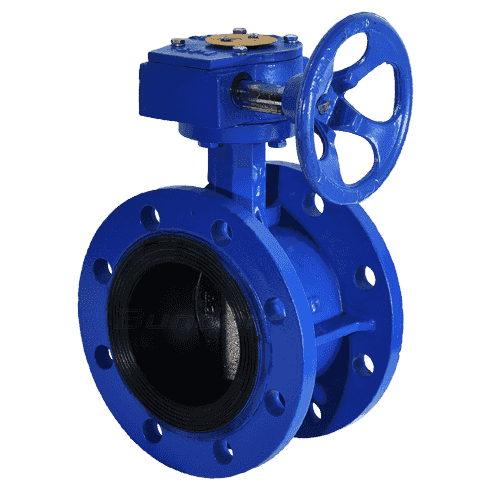

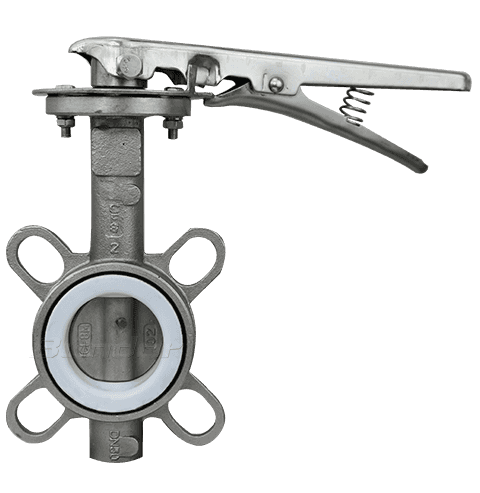

Eccentric flange butterfly valve is our new design, it is mainly used in the pipeline of water, power plants, steel smelting, chemical industry, papermaking, water projects, environmental facilities, etc. Especially used for regulation in water pipes and closure equipment.

Product Advantage

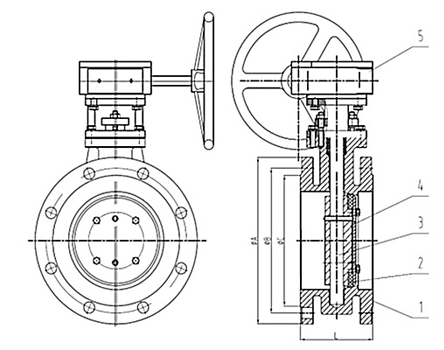

1, Reasonable design, compact structure, easy to assemble and repair

2, Eccentric structure, Reduce seal friction, extended service life

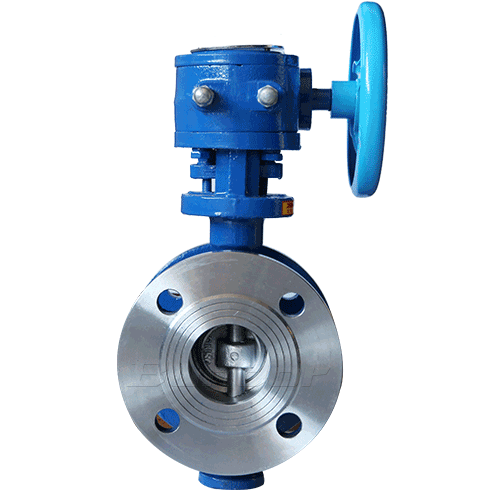

3, The valve disc seal with “T” type structure, sealing pair is linear sealing

4, Completely sealing, zero leakage

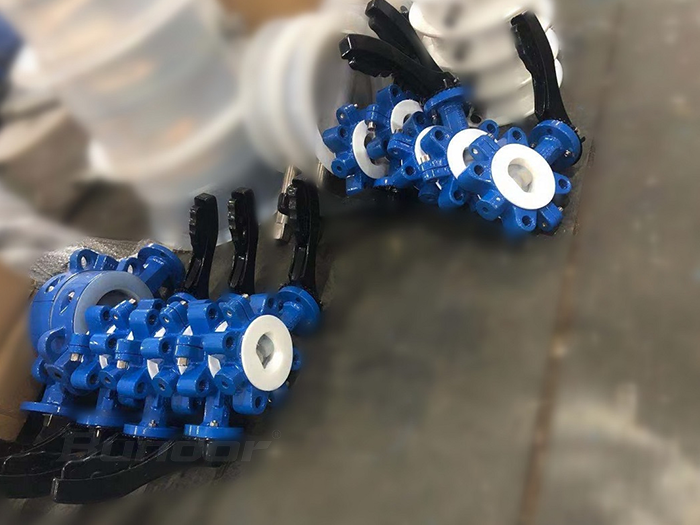

5, Replaceable sealing ring, O-ring, disc, stem and other parts to suit different medium and temperature

Standard Test

Body Test: 1.5 times the working pressure with water. This test is performed after valve assembly and with disc in half position open, it is called as a body hydro test.

Seat Test: 1.1 times the working pressure with water.

Function / Operation Test: At the time of final inspection, each valve and its actuator (Flow-Control Lever / Gear / Pneumatic Actuator), under goes a complete operating test (Open/Close). This test carried out without pressure and at ambient temperature. It ensures the correct operation of the valve / actuator assembly with accessories such as solenoid valve, limit switches, air filter regulator etc.

Special Test: On request, any other test can be carried out according to special instruction by client.